Virtual prototyping in the engineering process

PROBLEM

Standardise the engineering process and be able to create the layout of a new plant in the shortest possible time.

SOLUTION

Moxoff has developed a specific algorithm that supports companies in the quotation process by providing rapid cost evaluations based on the company’s past quotations and new outputs to evaluate new business scenarios.

+ Time reduction

+ User-friendliness

+ More efficient process

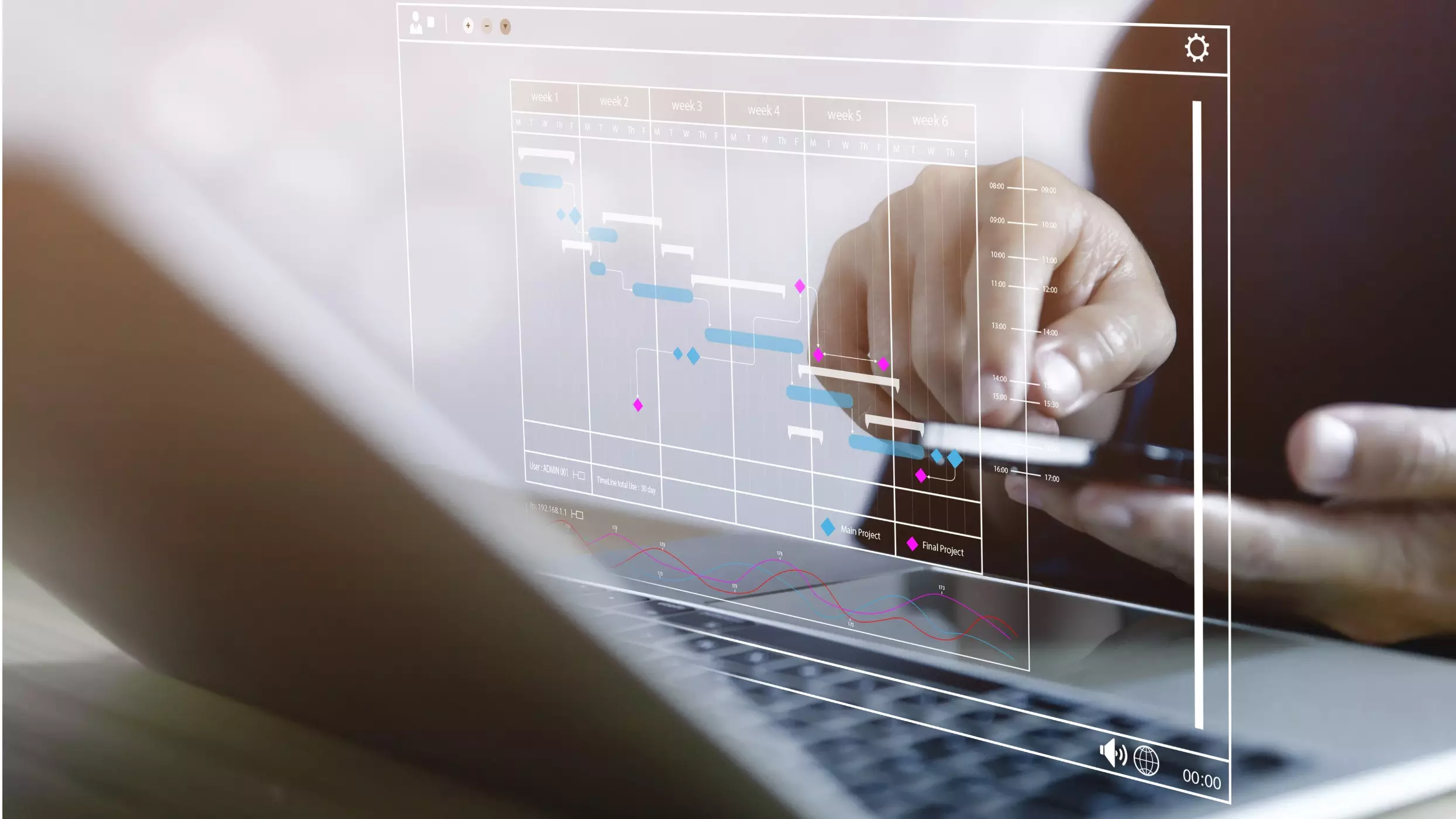

Production scheduling optimization

PROBLEM

Improving production processes, reducing machine downtime, optimising production times and reducing delivery delays.

SOLUTION

Moxoff has developed an streamlining algorithm that enables fast and effective scheduling of processes in compliance with the required criteria.

+ Reduction in machine downtime

+ Reduction of planning time

+ Increased competitiveness

Mathematical applied to liquid packaging machinery

PROBLEM

Improving the package forming and filling stages in a packaging system to preserve package integrity and filling accuracy.

SOLUTION

Reduced mathematical models were applied to the filling and packaging process of liquid bricks.

+ Time reduction

+ Smart-Integration

+ Forecasting

A mathematical evaluator for the large-scale plant design

PROBLEM

The need to automatically estimate the types and quantities of materials required for a new project.

SOLUTION

Developed an estimator that allows the total quantities of materials needed for the project to be calculated and provides details of the different parts and types of materials of which the overall plant is composed.

+ Quick quotations

+ More accurate planning

+ Greater estimating accuracy

Early warning to identify and manage product defects

PROBLEM

To provide customers with quality household appliances and guarantee fast and reliable after-sales service and maintenance at home.

SOLUTION

Moxoff has developed a fault prediction tool that can predict which component and when a fault is likely to occur.

+ Reduction of detection time – 50%.

+ Speeding up root cause of problems (from days to minutes)

Monitoring the performance of energy cables

PROBLEM

Increasingly reliable and controlled monitoring of the existing performance of installed cables.

SOLUTION

Moxoff has developed a tool that allows real time monitoring and automatic detection of anomalies.

+ Reduction of intervention times

+ Automatic monitoring

+ Flexible technologies

Mathematical estimator for made-to-order valves

PROBLEM

To respond with an accurate quotation in the quickest possible time.

SOLUTION

Moxoff has developed data-driven models to estimate, for each component, both the costs associated with raw materials and with all the processes involved, from assembly to final handling.

+ Rapid quotation

+ Design support

Mathematical models for optimising process quality

PROBLEM

Automated reporting of any potential system problems to minimise the risk of producing low-quality cables.

SOLUTION

Moxoff has provided mathematical modelling tools to support engineers in monitoring, predicting and improving all aspects of the manufacturing process that affect product quality.

+ Reduced analysis time

+ Improved quality

+ Reduced environmental impact cost

Remote monitoring of household appliance operation

PROBLEM

Ensuring an efficient and timely maintenance service.

SOLUTION

Moxoff has developed a tool to continuously and automatically monitor the functioning of household appliances.

+ 50% expected breakdowns

+ Accuracy

Optimization of the warehouse management

PROBLEM

Automating and improving the process of allocating a company’s products to its retailers worldwide to ensure buyers’ satisfaction, without affecting the entire supply process.

SOLUTION

Moxoff has developed such an algorithm that allows the customer to allocate products in a very short time.

+ Automatic allocation

+ Reduction of allocation time